Reducing waste to landfill is one of the most effective ways for industrial operations to improve sustainability performance, control costs and strengthen compliance. This case study outlines how Premier Waste partnered with Isuzu’s car manufacturing division to reduce general waste by 54%, increase resource recovery across key material streams and improve environmental outcomes within two years.

Many industrial sites face similar challenges, making effective commercial waste management essential for operational performance, compliance and environmental outcomes.

The Challenge: High General Waste, Rising Costs and Untapped Recycling Streams

Isuzu was looking to unlock cost savings by decreasing landfill waste while increasing diversion of recyclable and recoverable materials such as cardboard, timber, plastics and secure paper. In FY23, the waste profile was:

- General Waste: 71.70%

- Cardboard: 14.42%

- Timber: 5.99%

These results highlighted significant opportunities to improve recycling performance, lower disposal costs and strengthen sustainability outcomes. As EPA levies, landfill fees and CPI increased year-on-year, the business needed a structured approach to reduce general waste and lift recycling performance through smarter waste systems and behavioural change.

To address these challenges, Premier Waste analysed the site’s mixed waste streams, including opportunities to transition general waste into paper & cardboard recycling, commingled recycling, commercial & industrial waste and secure destruction streams such as secure document destruction.

Our Approach: A Behaviour-Led Waste Reduction Strategy

Premier Waste partnered with Isuzu to introduce a structured, engagement-driven waste improvement program. The objective was to embed long-term changes in staff behaviour, improve waste segregation practices and create clear ownership across departments.

Key elements included:

- Establishing a strong collaborative model with site leadership

- Appointing on-site waste champions to drive accountability

- Delivering tailored training to operational teams

- Conducting regular waste performance tracking and reviews

- Facilitating on-site engagement sessions to troubleshoot and reinforce best practice

This method ensured engagement at every level, from operational staff through to management, enabling the results to be sustained long-term.

The Impact: Major Reduction in Landfill Waste

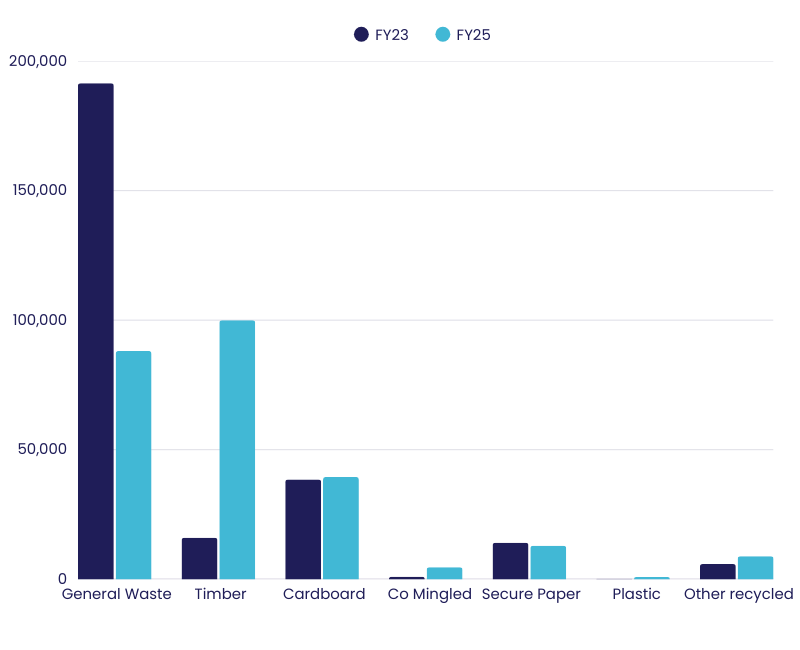

Isuzu achieved measurable improvements across all material streams between FY23 and FY25:

Key outcomes:

- 54% reduction in General Waste (191,470 kg to 88,117 kg)

- Timber recovery increased from 16,000 kg to 100,000 kg, processed into woodchips and mulch through a Premier Waste partner

- 3,611 kg increase in commingled recycling, improving overall diversion

- Diversion rate increased from 28.30% to 60.18%, more than doubling in two years

These results were primarily driven by better segregation, enhanced behaviour, and consistent staff engagement.

Material Performance (FY23 vs FY25)

| Waste Stream | FY23 | FY25 | Change |

|---|---|---|---|

| General Waste | 191,470 kg | 88,117 kg | ⬇ 54% |

| Timber | 16,000 kg | 100,000 kg | ⬆ 525% |

| Cardboard | 38,500 kg | 39,465 kg | ⬆ 2.5% |

| Secure Paper | 14,093 kg | 12,944 kg | ⬇ 8% |

| Plastic | 140 kg | 840 kg | ⬆ 500% |

| Commingled | 979 kg | 4,590 kg | ⬆ 368% |

| Other Recycled | 5,868 kg | 8,835 kg | ⬆ 51% |

| Other Landfill | 16 kg | 2 kg | ⬇ 88% |

**Based on financial year data.

Cost Savings Despite Rising Industry Costs

Although industry-wide pressures (landfill levies, EPA compliance costs, CPI) increased the cost of waste disposal, Isuzu still achieved a reduction in annual waste expenditure:

Annual waste costs decreased from $161,000 in FY23 to $149,000 in FY25.

These savings were driven by reduced landfill tonnage, improved source separation and optimised service scheduling — even as industry costs rose around them.

For other businesses wanting similar results, Premier Waste offers tailored waste management services across Melbourne & Brisbane.

Emissions Reduction & Environmental Impact

By reducing general waste sent to landfill, the site avoided 116.48 tonnes of greenhouse gas emissions.

This calculation uses the Australian National Greenhouse Accounts emissions factor of 1.3, reflecting the environmental benefit achieved through increased diversion and reduced reliance on landfill disposal.

Why This Worked: Key Success Factors

This project proved that meaningful waste reduction is driven by behaviour, education and clear processes — not just infrastructure.

What enabled success:

- High accountability across teams

- Clear communication and support from leadership

- Waste champions driving standards onsite

- Regular reporting and waste analytics

- Strong partnership between Premier Waste and the client

This structure ensured improvements were not temporary but embedded into daily operations.

Key Learnings for Industrial Waste Management

The results were driven by a combination of behavioural change, operational ownership and structured support.

The key enablers included:

- Clear leadership commitment

- Site waste champions supporting daily practices

- Ongoing behavioural reinforcement

- Transparent reporting and data-driven decision-making

- Engagement sessions that built staff understanding and accountability

This model shows how targeted behaviour change can drive significant waste performance improvements at industrial scale.

“By maintaining such a controlled cost structure in a volatile environment, they’ve demonstrated the true value of strategic waste management and operational efficiency.”

— Drago Manjerovic, Major Account Manager

Download the Full Case Study

For the full methodology, waste analytics and detailed breakdown:

You must be logged in to post a comment.